The electrical impedance tomography hardware system was designed to include STM series development board modules, an electricity voltage-controlled current source module, and an analog multiplexer module. Two types of electrode sensors were designed for different detection objects: sink electrode sensors and bracelet electrode sensors. The design of the bracelet sensor focused on minimizing contact impedance. To ensure high portability of the system, a laboratory box was designed. The developed electrical impedance tomography hardware system was then tested for portability using an electrical impedance tomography system and a high-precision impedance analyzer.

Orange as Test Unit

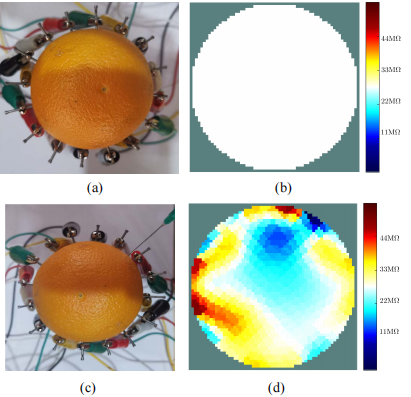

Test of the proposed electrical impedance tomography (EIT) system was performed using an orange as the test object. The following four scenarios were tested: (a) orange in the calibration plane, (b) image reconstruction of the orange in the calibration plane, (c) orange with seawater injected, and (d) image reconstruction of the orange with seawater injected.

To perform calibration, a test unit (vessel) filled with conductive water only was used

My main responsibilities include PCB drawing, hardware circuit construction, and debugging, as well as multiplex selector design. In this role, I am committed to learning both airplane algorithms and hardware circuit design.